This post-processing step is necessary when using certain proprietary machine control languages which may differ from language conventions established by popular generic CAD/CAM Software packages like Autodesk Fusion 360 or Mastercam. In some cases post-processing may also be done on the tool path data before it can be sent directly from CAM software into CNC machines for execution. This toolpath data is then sent directly to CNC machines which allows them to automatically execute each step in order according to predetermined instructions without human intervention. Once these parameters have been entered the software will then generate an appropriate tool path that will direct how each operation should take place according to these specifications. In general CAM software works by first inputting information about the project into its GUI such as size specifications, material properties, cut depth etc. Additionally, by optimizing the tool paths generated by CAM software according to specific materials being used and machines being used for machining (CNC Machines), greater efficiency can be achieved in terms of overall cycle times when compared to manual methods. By automating aspects of the design process such as toolpaths, speeds and feeds calculations, machine setup parameters etc., it helps reduce errors associated with manual data entry or keystroke miscalculations. The main purpose of CAM software is to help increase productivity through improved planning capabilities.

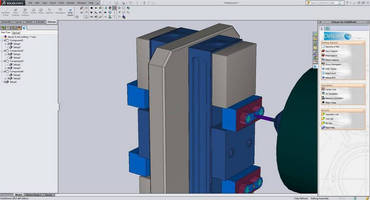

CAM software typically consists of a graphical user interface (GUI) with a set of tools for creating a digital representation of a part or product that can be created in real time from physical stock materials without any additional programming steps.

It is used to automate and improve the accuracy and efficiency of production processes, such as machining, stamping, cutting, forming, drilling, grinding and finishing.

Computer-Aided Manufacturing (CAM) Software OverviewĬomputer-aided manufacturing (CAM) software is a type of computer technology designed to assist in the production process.

0 kommentar(er)

0 kommentar(er)